"Michael Woyahn" (michaelwoyahn)

"Michael Woyahn" (michaelwoyahn)

09/03/2015 at 08:00 ē Filed to: None

12

12

10

10

"Michael Woyahn" (michaelwoyahn)

"Michael Woyahn" (michaelwoyahn)

09/03/2015 at 08:00 ē Filed to: None |  12 12

|  10 10 |

I recently went for a ride in a Camaro ZL1 and it was absolutely stunning. The way its 580 hp slams you into the suede bucket seats, how easily it breaks the rear tires loose, and the glorious sound of the eight cylinders churning away in the engine block all added together to create an unforgettable experience.

And then we got back into my familyís !!!error: Indecipherable SUB-paragraph formatting!!! . This made me realize something, other than the fact that the RAV4 is slower than a barge towed by a pontoon boat. It made me realize that all cars are amazing.

Thatís right. The 1999 Chevy Cavalier sitting at your neighborhoodís sketchiest car dealership is amazing. The redesigned Prius that looks like the love child of Captain Hook and a Praying Mantis is amazing. The Cadillac Escalade thatís currently being driven to the grocery store by an upper class, stay-at-home mom is amazing.

Think about it. In order for a car to be birthed into existence, it needs to start off as an idea. Someone in the company says, ďHey. I think we need to make a compact sedan because gas prices will probably go up.Ē You can fill in the blank with any type of car that fits in with the trends of the market: a hatchback, a SUV, a coupe, a SUV coupe, which seems to be the craze now, or whatever your heart desires.

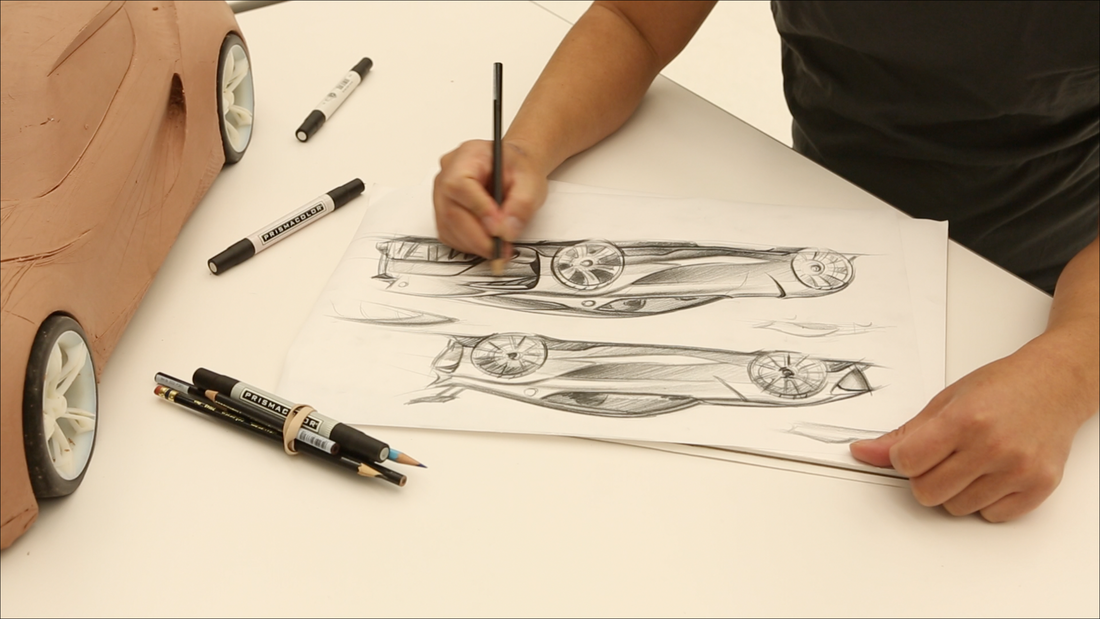

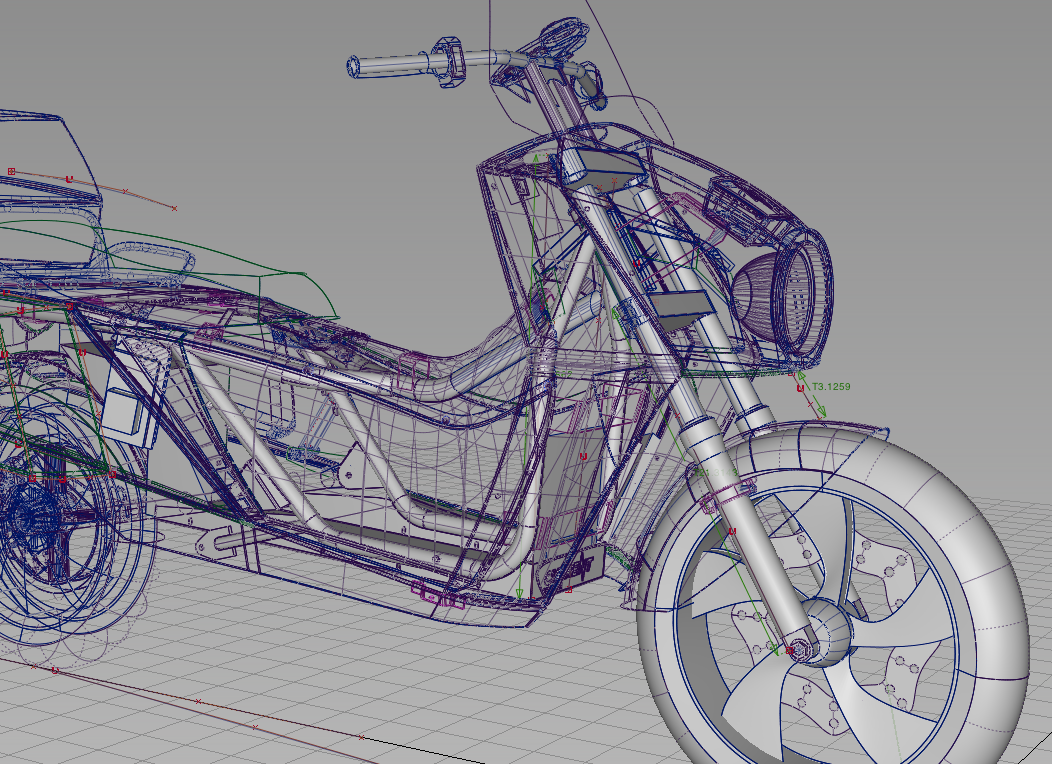

A designer then crafts the first sketches with meticulous strokes of a pencil, or in Lexusís case, chops of an axe. The initial sketches are then toned down in order to realistically fit engines, drivetrains, and safety equipment. Once everything can be crammed in, it is brought into the three-dimensional world with a computer rendering. After this, the designers create a full sized model of the car. This is typically made of clay, but plastics and other materials can be used to create a concept car thatís displayed at auto shows.

The next step is the interior, which follows a journey similar to the exterior. Typically, the original designer sketches it alongside the exterior. Again, it has to be adjusted to be more realistic and is eventually brought to life with computer and clay models. Interestingly, this is when material, trim, and color choices are finalized. But, before the designers sign the bill and set the interior choices in stone, the different materials have to be tested to make sure they hold up to everyday wear and tear.

Now comes testing the cars in their near final forms. This is when you see cars running around Death Valley or Norway in black and white camouflage suits. Companies have to test cars to see how they handle hot and cold weather, snow, rain, direct sunlight, and anything else you may experience in the real world. If a part fails in some way, the company has to find another material that works. When the materials are set, the car then needs to be crash tested.

Once the car passes every single test the manufacturer can dream up, the next step is getting the A-Okay from management to produce this car. After that, itís off to the factories to make little changes to a carís design in order to make its production easier and cheaper. Now, after three to five years of development, the car is ready to hit dealership lots. Keep in mind, I only talked about the design of the car. Thereís also the suspension, engine, and drivetrain development that has to go along with it.

The amazing part of a carís development is that, essentially, the same amount of time and effort goes into every car. A $13,000 car gets the same attention as a $60,000 car. Car manufacturers have to decide what sacrifices need to be made in order to keep prices as low as possible, while still developing the cars to an acceptable standard. This standard is based off of the carís ultimate job, so obviously the same rules donít apply to $200,000 super cars or cruisers.

If a company is making a little city car, less time will be spent on sound deadening at high speeds when compared to a luxury car. If a company is making a hybrid, more of their focus will be on the powertrain and aerodynamics. Of course, different companies have different budgets too. Larger companies like Toyota or Volkswagen will naturally have larger sums of money to play with during development.

Hereís what is so fascinating about cars to me. Every single one has their own purpose and this purpose has to be in the mind of manufacturers in every step of creation process. Some are family haulers, some are desert bashing off roaders, some are commuters, some are two seat sports cars, and some arenít even sure what they are. But they all had to make it through this long process, despite the different price points and categories. Each car on the road today had a chance of being killed off before they ever saw the light of an auto show and it makes me wonder what ones ended up as stillborns.

Thanks to Torque News for the information. If you want more details on the process of designing cars, check out this !!!error: Indecipherable SUB-paragraph formatting!!! .

Photo credits in order: Art of the Automobile Tumblr, The Verge, Automotive Addicts, Carbodydesign, Autoblog, Wyatt Johnson Subaru, and Transportation Research Center

Twingo Tamer - About to descend into project car hell.

> Michael Woyahn

Twingo Tamer - About to descend into project car hell.

> Michael Woyahn

09/03/2015 at 08:07 |

|

Or in the case of Fiat the car design is scrawled on the wrapper of a Peroni bottle and assembled by poorly trained monkeys armed only with rocks.

Chris_K_F drives an FR-Slow

> Twingo Tamer - About to descend into project car hell.

Chris_K_F drives an FR-Slow

> Twingo Tamer - About to descend into project car hell.

09/03/2015 at 08:18 |

|

If we had an Oppo COTD, this would win today.

Montalvo

> Michael Woyahn

Montalvo

> Michael Woyahn

09/03/2015 at 08:29 |

|

I always thought all cars (not electric) at least have something going for them not just because of the design phase but because of combustion. Think about it the exhaust of a car is literally the last roar of a dinosaur (bio matter) which died so long ago, compressed so much it turned into liquid, got dragged up to the surface to be exploded and produce power. You are literally being propelled by an explosion made from dinosaurs. If that doesnít sound cool to you, you must be an absolute blast at parties...

philsphan09

> Michael Woyahn

philsphan09

> Michael Woyahn

09/03/2015 at 08:36 |

|

Iíd argue a $13K car does not get the same treatment as a $60K car. Look at the GM Ignition issues for instance.

Jayhawk Jake

> Michael Woyahn

Jayhawk Jake

> Michael Woyahn

09/03/2015 at 08:45 |

|

You skipped engineering. The step where engineers turn a designers sketch into an actual car.

Itís what I love about what I do. We have a sleek aerodynamic exterior crammed with structure and systems. Itís beautiful how all the pieces come together to make a machine

https://www.flightglobal.com/assets/getasseÖ

TheRealBicycleBuck

> Michael Woyahn

TheRealBicycleBuck

> Michael Woyahn

09/03/2015 at 09:08 |

|

No. EVERYTHING is amazing now. Louis, I agree with you 1,000%.

ChooChooMotherFudger

> Jayhawk Jake

ChooChooMotherFudger

> Jayhawk Jake

09/03/2015 at 09:19 |

|

As and engineering student, I have learned that most of what we need to do is packaging.

Milky

> Jayhawk Jake

Milky

> Jayhawk Jake

09/03/2015 at 09:39 |

|

Or in the case of some smaller companies, the designers have to be an engineer.

What the fuck did I get myself into?!

Michael Woyahn

> Jayhawk Jake

Michael Woyahn

> Jayhawk Jake

09/03/2015 at 10:24 |

|

Youíre right. There are tons of other parts of the manufacturing process that I skipped over in this post.

But it is just fascinating how much stuff is going on underneath what everyone sees and it all works together perfectly.

Michael Woyahn

> philsphan09

Michael Woyahn

> philsphan09

09/03/2015 at 10:47 |

|

I agree with you, to an extent. I think that roughly the same amount of time is spent with new vehicle development in each car, unless it is deliberately rushed. The rushing was more of a case with earlier economy cars, but now manufacturers canít even let their cheap cars feel cheap, so theyíre spending more time on them.

But youíre right, there are definitely cases of different treatment. Especially with the GM ignition problems.